Precise

cooling solutions for maximum process reliability

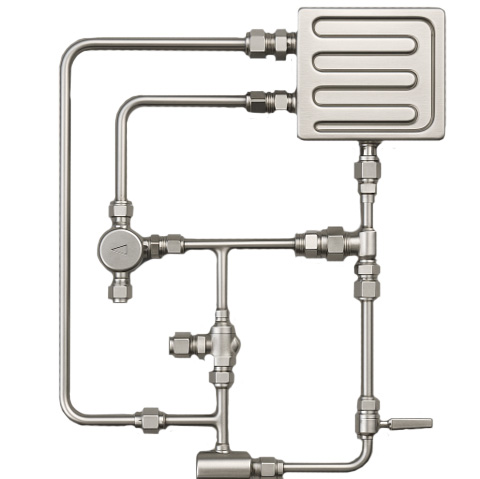

Liquid cooling with a system

Cooling circuits are the backbone of

thermally stable processes, particularly where performance, precision and

reliability are required, such as in semiconductor manufacturing, medical

technology or e-mobility. With the technological transition from air cooling to

liquid cooling, requirements in terms of impermeability, material compatibility

and system integration have become stricter.

We supplie modular components and tube

unions for liquid cooling systems. Our systems prove their worth in millions of

sealing points every day: they are reliable, durable and low-maintenance.

Their compact construction, high resistance

to media and easy-to-assemble design mean that your cooling will

remain impermeable over the long term. This boosts performance, minimises

downtime and saves valuable space in your system construction.

We do more than support our customers with

premium components: we also help them design and realise optimum cooling

systems that are precisely tailored to their requirements.

This goes from selecting the appropriate

catalogue parts via developing specific custom solutions to advising on system

configurations. EXMAR delivers more than individual parts. We deliver ready-to-fit

complete solutions with excellent technical, thermal and economic

properties.

Overview

of the core components

Key

components for your cooling circuit

- Union technology

Can be mounted radially, low-maintenance, compatible with vacuums and high pressures, made from stainless steel, brass, aluminium and PVDF - Valve

technology

Non-return valves, regulating valves, overflow valves and ball valves. All materials - Quick-close

unions

Quickly uncouple media while the system is running using unions made from stainless steel, brass and PVDF - Tubes

curved tubes, assembled, cleaned, mounted as a kit

precision tubes from stainless steel, copper and aluminium - Hose

lines

PTFE, FEP, PFA, stainless steel wire-overbraided hoses. Custom-assembled for each customer - Distributors

Made to customer specification, with no compromise. From 1 to 10,000 units. The right solution for the quantity and the medium required

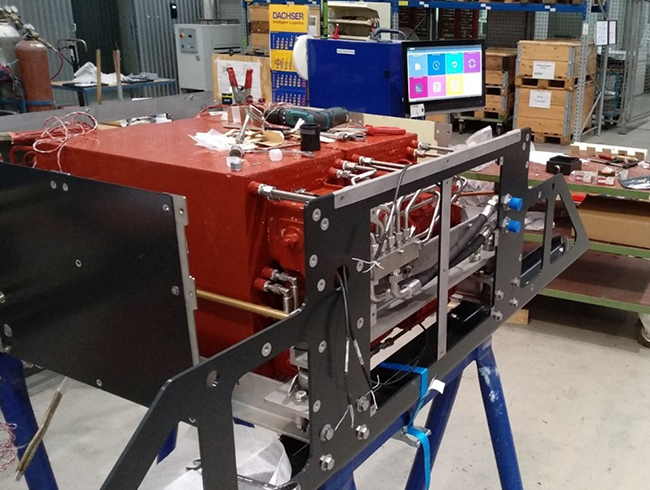

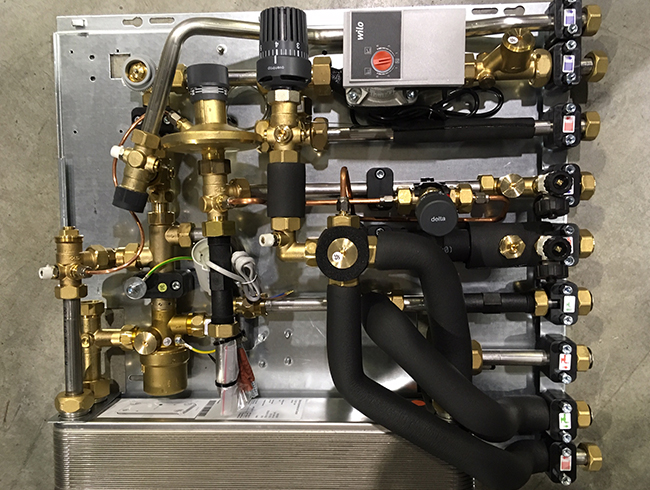

Cooling

solutions – ready to fit

For viscous media, narrow installation

spaces or high thermal loads, we can design a cooling system to meet your

precise requirements in terms of the medium, temperature, pressure and

installation location. From selecting the appropriate catalogue parts to

developing customer-specific custom components, we deliver preassembled systems

that can be incorporated straight away. As a system supplier with our own

manufacturing processes, we can react flexibly to any requirement.

You can rely on our assembly skills. We combine standard and

third-party components to form tested assemblies that are ready for

installation, including handling the planning, manufacturing and logistics. In

addition to component assembly, we also supply ready-to-install pipelines:

curved, compressed and fitted with unions, valves, ball valves or couplings

from the EXMAR and SERTO ranges. Your tubes will arrive at the correct size,

cleaned and pressure-tested – ready for use straight away. This saves you

assembly time and maximises the safety of your facility.

Your benefits?

Impermeable

& reliable

Leakage-free, even with viscous media.

Millions of components have been in use for decades.

Corrosion-resistant

Compatible with ultrapure water, glycol

& aggressive media.

Material used selected based on medium

& temperature.

Compact

& space-saving

Ideal for narrow installation spaces, e.g.

battery modules.

Less room taken up by cooling technology means more room for electronics.

Temperature-

& pressure-resistant

Catalogue values exceed system

requirements.

Stainless steel, brass, aluminium & PVDF depending on application.

Easy

to assemble, low maintenance required

Use unions instead of welding – quick,

clean and reversible.

Components can be swapped out during operation without the need for special

tools.

Safe

& compliant with standards

Impossible to install incorrectly, even for

non-specialised personnel.

DVGW [German Technical and Scientific Association for Gas and Water]-compliant,

industrially documented.

Use Cases

Sectors

and applications

Used in the most demanding environments,

from semiconductor technology via optics systems to data centres. Our cooling

components and system solutions are used wherever thermal stability determines

process quality.

Semiconductor industry

Lithography equipment

Plasma chambers

Laser

technology/optics systems

Laser diodes

Sensors

Machine

tools / spindle cooling

Machine components

Food technology/packaging

Cold water circuits

Temperature regulation systems

Industry / Automation

Power electronics

Propulsion systems

E-mobility

Battery modules

Power electronics

Data

centres

Server racks (rack- or chip-level)

Electricity

Charging stations

Drives

(Railway) chokes

Heating

Sterilisation

Temperature regulation devices (injection

moulding, chocolate)

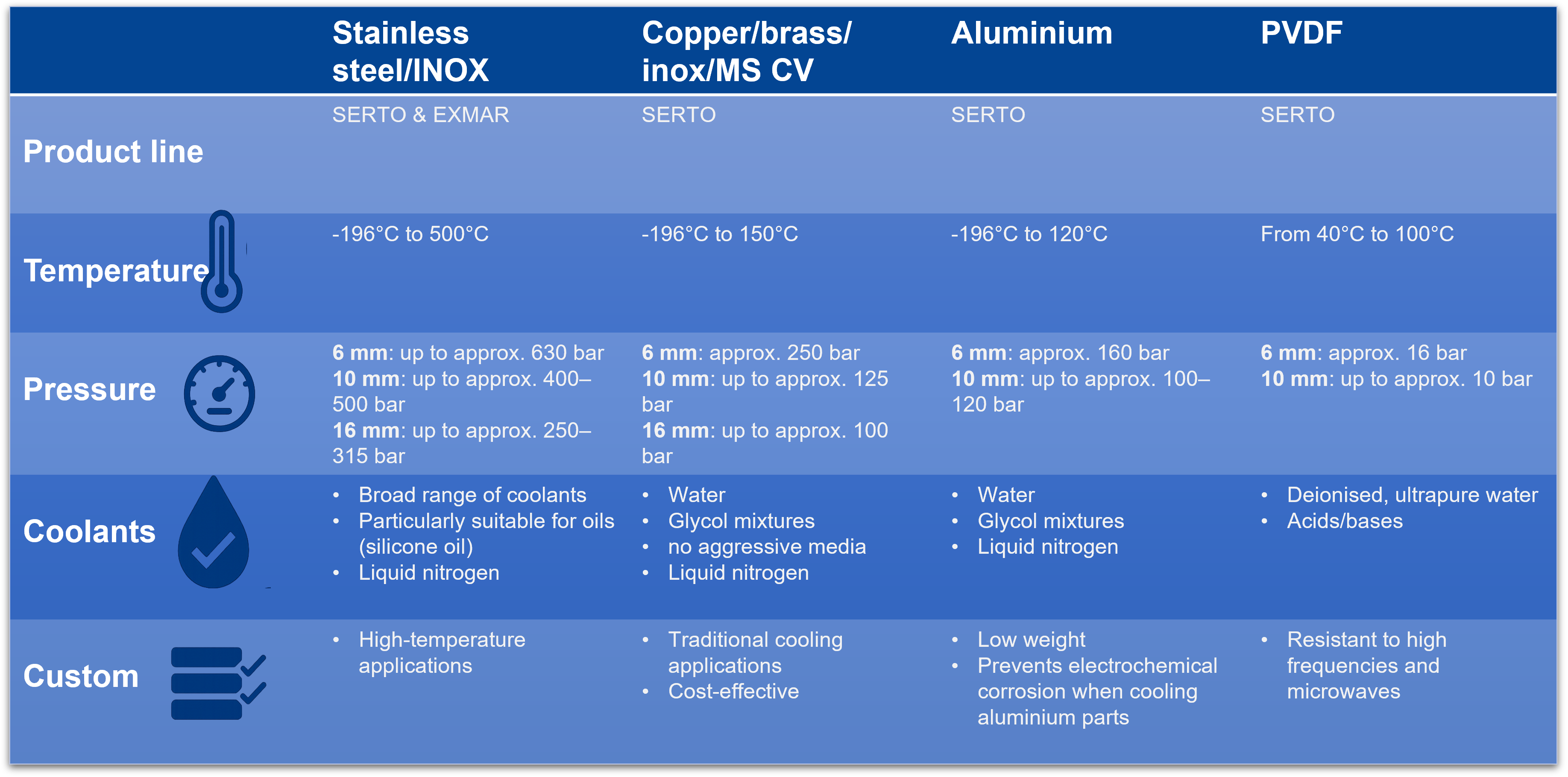

Selection Guide

Our components are available in various

materials, depending on the temperature ranges, pressure requirements and

chemical resistance required. The Selection Guide gives you a quick overview of

the essential properties of our stainless steel, copper, aluminium and PVDF

product lines. This allows you to find the suitable material for your cooling

medium, your application and your system requirements.