Shipbuilding and onshore/offshore facilities

Your product and development partner

The materials used in vessels, onshore and offshore facilities operating in rough waters need to withstand seawater, corrosion and fatigue. Design engineering is another shipbuilding challenge: The complexity of shapes and structures demand greatest precision and accuracy.

We provide smart products and technologies for all vessel, onshore and offshore applications. EXMAR components and systems are used for ship and yacht building, in oil and gas production facilities and in wharf and harbour equipment Our unions and fittings have been approved by globally acknowledged classification bodies. Many years of experience in system design and optimisation coupled with pre-assembled pipelines make EXMAR your perfect product and development partner.

Examples of shipbuilding and onshore/offshore facility customer applications

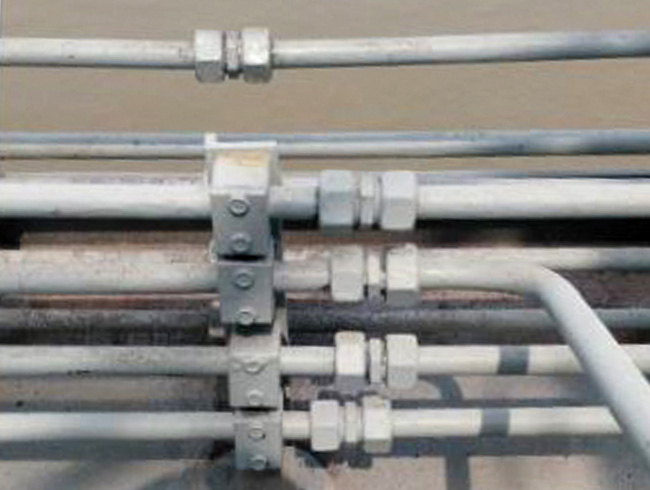

Installation of hydraulic pipes in deck machinery

EXMAR products

Clamping ring fittings, cutting ring fittings, prefabricated stainless steel pipes

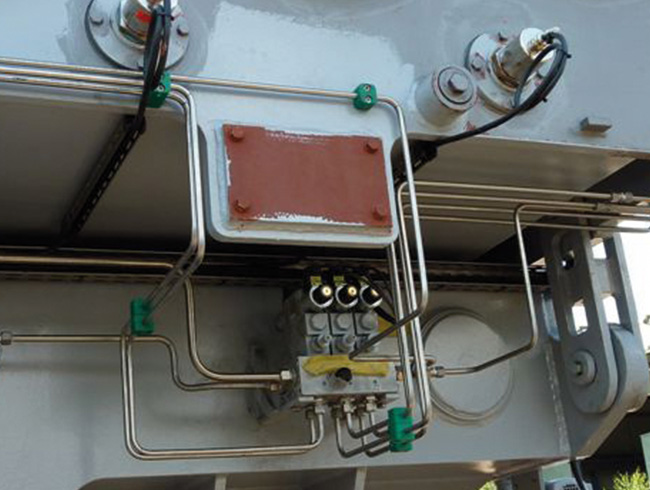

Waterproof doors and deck machinery of semi-submersible salvage vessels

EXMAR products

Clamping ring fittings, cutting ring fittings, prefabricated stainless steel pipes

Hydraulic piping of on-board and quayside loading facilities

EXMAR products

Clamping ring fittings, cutting ring fittings, prefabricated stainless steel pipes

Crane barge capstan

EXMAR products

Clamping ring fittings, cutting ring fittings, prefabricated stainless steel pipes

Product Highlights

Customer testimonials

“We installed EXMAR fittings in high-pressure water pump units for pressure testers at wharfs. EXMAR has left a very good impression on us, be it due to fast delivery or their competitive price.”

Industry-specific approvals and confirmations

- DNV

- American Bureau of Shipping (ABS)

- Bureau Veritas (BV)

- China Classification Society (CCS)

- RMRS Approval

- LLyod’s Register

Services

System solutions

Ready-to-install pipelines and kits

Bending pipes

We also provide...

- Electronic ordering process

- Individual logistics solutions: Kanban system, delivery schedules

- Batch traceability: 3.1 Certificates

- Customized testing equipment (helium leakage test, bending fatigue strength, flow, vibration, burst pressure, climate and many more)

Industry expertise

You can rely on our product and material skills!

Our experts can provide targeted support ...

- with comprehensive expertise in design and technology

- in selecting suitable products, materials and processing steps

- with individual logistics concepts

- in developing tailored systems and kits

- that meet your requirements