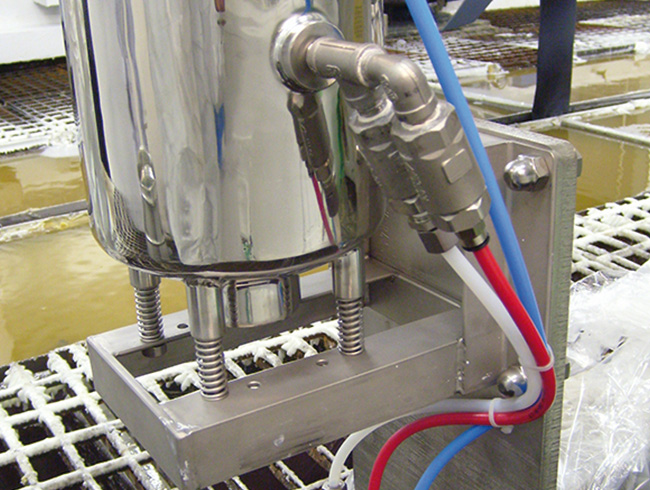

Dosing and painting equipment

Your product and development partner

Many industries make use of dosing equipment, for example for chemicals or for foodstuff and water. EXMAR products are chemically extremely resistant to all customary media. Operating pressures of our unions, ball valves and check valves range up to 500 bar.

Painting equipment must meet strictest requirements as regards surface purity. Since silicone compounds will prevent the reliable wetting of surfaces, EXMAR provides unlubricated components.

We provide smart products and technologies for all dosing and painting equipment applications. EXMAR components and systems are used for painting and irrigation systems as well as for gas and liquid filling systems. Many years of experience in system design and optimisation coupled with pre-assembled pipelines make EXMAR your perfect product and development partner.

Examples of dosing and painting equipment customer applications

Color changer

EXMAR products

Clamping ring fittings, cutting ring fittings

Paint supply lines

EXMAR products

Clamping ring fittings, cutting ring fittings, valves and needle valves

Varnish supply system / varnish mixing room

EXMAR products

Clamping ring fittings, cutting ring fittings, valves and needle valves, prefabricated stainless steel pipes

Non-contact cleaning of an automatic gun’s air flap

EXMAR products

Clamping ring fittings, cutting ring fittings, valves and needle valves

Product Highlights

Customer testimonials

“EXMAR is a powerful partner at last, who we will keep relying on in future applications. We particularly appreciate EXMAR’s excellent supply capacity, reliability, flexibility and the outstanding quality of their products.”

“We are delighted to use EXMAR fittings in our key automotive project featuring a miniature varnish supply unit. EXMAR excels in their delivery times and their large warehouse in Shanghai. We therefore need not import these products from Europe and save time and money. Not to forget the quality of EXMAR’s products.”

Services

System solutions

Ready-to-install pipelines and kits

We also provide...

- Electronic ordering process

- Individual logistics solutions: Kanban system, delivery schedules

- Batch traceability: 3.1 Certificates

- Customised testing equipment (helium leakage test, bending fatigue strength, flow, vibration, burst pressure, climate and many more)

Industry expertise

You can rely on our product and material skills!

Our experts can provide targeted support ...

- with comprehensive expertise in design and technology

- in selecting suitable products, materials and processing steps

- with individual logistics concepts

- in developing tailored systems and kits

- that meet your requirements