Environmental technology

Your product and development partner

The environmental technology industry adds or withdraws water, acids and bases. Safe applications mainly depend on how tight the system is. If all components are perfectly matched and if pipes are made with high-quality workmanship and installed professionally, both metallic and soft sealing EXMAR unions will stay tight down to at least 10-7mbar l/s (cutting ring fittings) respectively to at least 10-8mbar l/s (clamping ring fittings) and leave a safety margin up to fourfold the standard pressure.

We provide smart products and technologies for all environmental technology applications. EXMAR components and systems are used for water treatment, in purification, waste incineration and recycling. Many years of experience in system design and optimisation coupled with ready-to-install kits make EXMAR your perfect product and development partner.

Examples of environmental technology industry customer applications

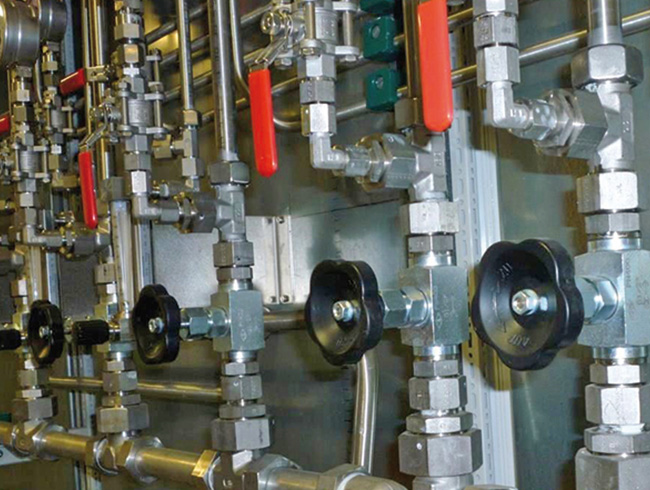

Mixing and distributing module in an exhaust cleaning system

EXMAR products

Clamping ring fittings, cutting ring fittings, valves and needle valves

Dosing system for purification plants

EXMAR products

Clamping ring fittings, cutting ring fittings, valves, pre-assembled stainless steel tubes

Rotation heat pump

EXMAR products

Clamping ring fittings, cutting ring fittings, pre-assembled stainless steel tubes

Product Highlights

Customer testimonials

“Using the NC clamping ring fittings from EXMAR’s modular system and the tailored 8-way/16-way stainless steel manifolds has provided us with high-quality stainless steel components for easily installing our durable and permanently tight ventilation and air conditioning system in a ventilation and air conditioning duct. Working with EXMAR and seeing their flexibility of design and realisation of customised special parts at work was an exquisite experience. EXMAR helped us sustainably optimise our system and put our sales figures on an ongoing incline.”

Services

System solutions

Ready-to-install pipelines and kits

We also provide...

- Electronic ordering process

- Individual logistics solutions: Kanban system, delivery schedules

- Batch traceability: 3.1 Certificates

- Customised testing equipment (helium leakage test, bending fatigue strength, flow, vibration, burst pressure, climate and many more)

Industry expertise

You can rely on our product and material skills!

Our experts can provide targeted support ...

- with comprehensive expertise in design and technology

- in selecting suitable products, materials and processing steps

- with individual logistics concepts

- in developing tailored systems and kits

- that meet your requirements