Mechanical and plant engineering

Your product and development partner

Mechanical and plant engineering has to face the challenge of reinventing the entire design process. Increasing price pressure forces us to sharpen our focus if we are to maintain or perhaps to improve our profit margins. Engineers go a long way to design and optimize various subsystems before the machines actually start being made.

We provide smart products and technologies for all mechanical and plant engineering applications. EXMAR components and systems are used in pumps, compressors, large diesel engines, presses or machine tools. Many years of experience in system design and optimization, pre-assembled pipelines and ready-to-install assembles make EXMAR your perfect product and development partner.

Examples of mechanical and plant engineering customer applications

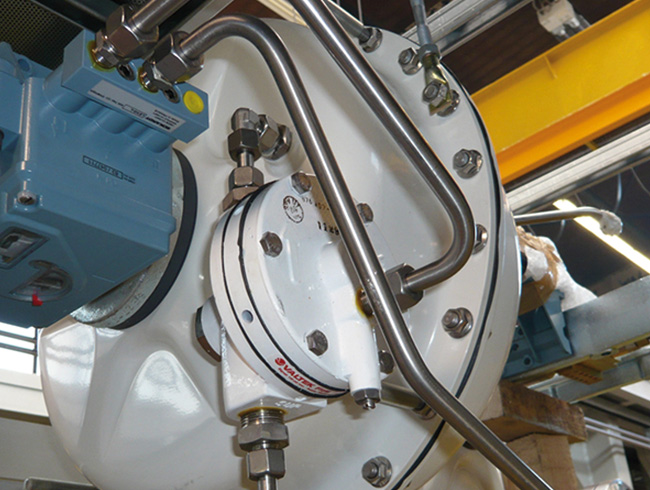

Pressure gas governor (PN100) with measuring and control lines

EXMAR products

Clamping ring fittings, cutting ring fittings, pre-assembled stainless steel tube

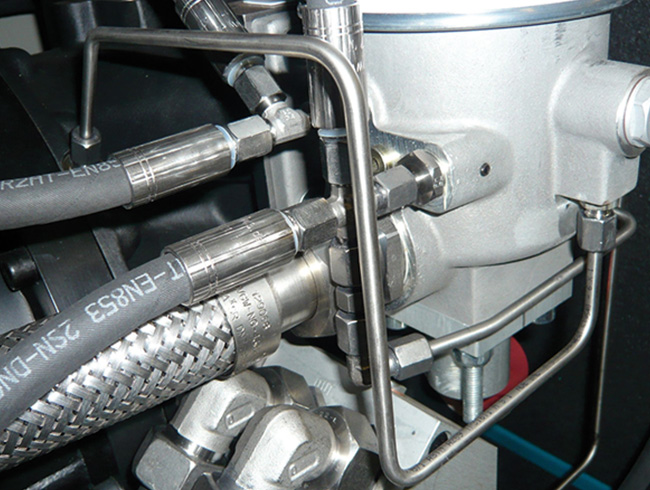

Special enclosure for separating oil/biogas

EXMAR products

Clamping ring fittings, cutting ring fittings, valves, prefabricated stainless steel pipes, prefabricated hydraulic hoses

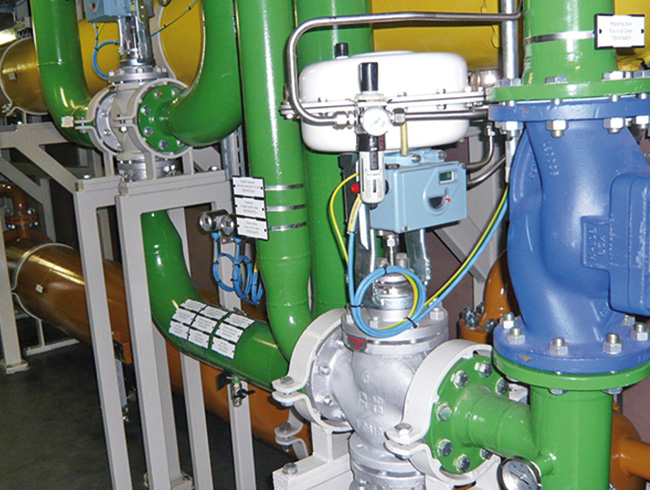

Natural gas compressor for gas turbine supply

EXMAR products

Clamping ring fittings, cutting ring fittings, valves, prefabricated stainless steel pipes

Combined cycle generator in a power plant

EXMAR products

Clamping ring fittings, cutting ring fittings, valves and needle valves, prefabricated stainless steel pipes

Product Highlights

Customer testimonials

“The close cooperation has persuaded us to rely on our partner EXMAR from the development phase up to the installation of the finished products. EXMAR offers a very good price-performance ratio and delivers on schedule, and above all with a reliable quality. The items that we need can be delivered immediately even in large numbers. Our production times are minimized and the costs are lowered thanks to the close cooperation with the EXMAR team.”

“I am extremely satisfied with using EXMAR fittings in two major overseas projects. EXMAR has left a very good impression on us, be it due to fast deliveries or their technical support. Whatever the technical challenge – EXMAR responded swiftly and designed a professional solution.”

Services

System solutions

Ready-to-install pipelines and kits

Bending pipes

We also provide...

- Electronic ordering process

- Individual logistics solutions: Kanban system, delivery schedules

- Batch traceability: 3.1 Certificates

- Customized testing equipment (helium leakage test, bending fatigue strength, flow, vibration, burst pressure, climate and many more)

Industry expertise

You can rely on our product and material skills!

Our experts can provide targeted support ...

- with comprehensive expertise in design and technology

- in selecting suitable products, materials and processing steps

- with individual logistics concepts

- in developing tailored systems and kits

- that meet your requirements